Industrial Coffee Grinder for High-Volume Brewing: A Necessary Tool

Industrial Coffee Grinder for High-Volume Brewing: A Necessary Tool

Blog Article

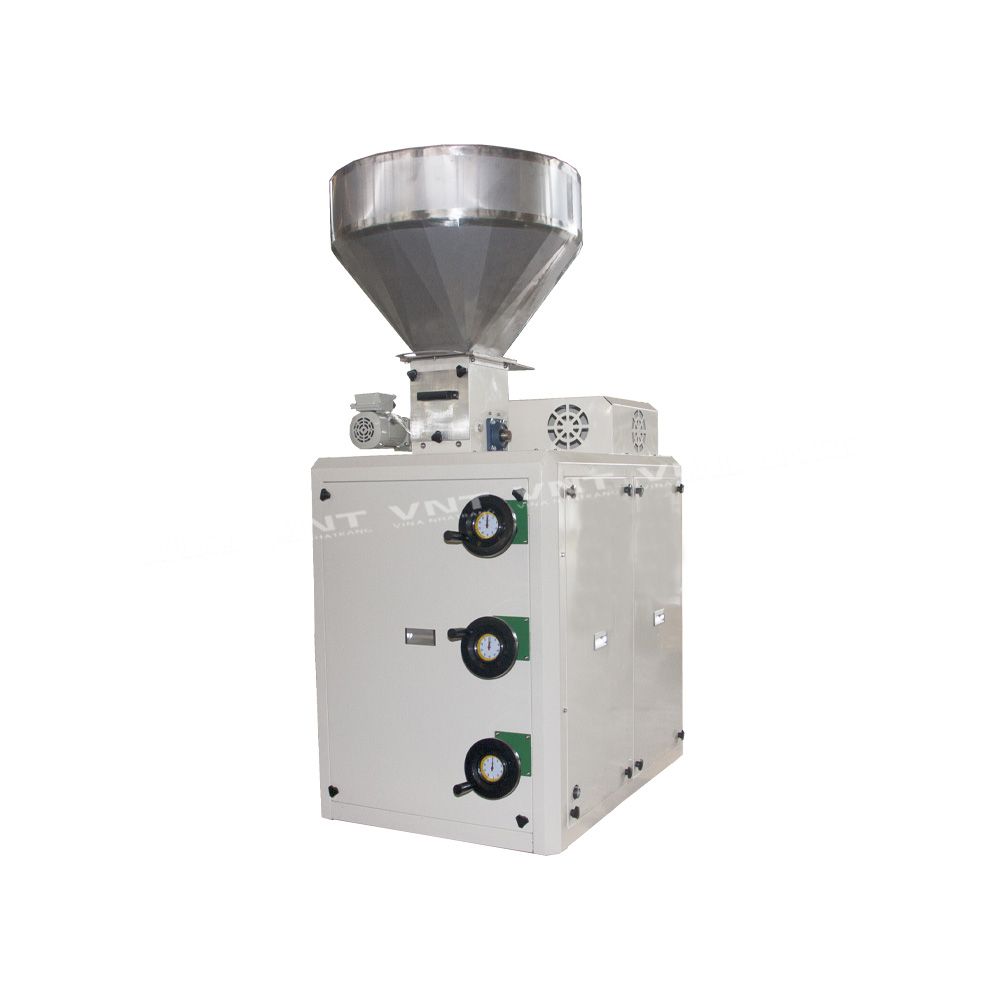

Industrial Coffee Mill Guide: Increase Efficiency and High Quality

In the competitive landscape of coffee manufacturing, picking the best commercial coffee grinder plays an essential role in improving both performance and product high quality. Understanding the subtleties of various grinder kinds and vital functions-- such as personalized grind settings and robust building and construction-- can significantly influence the final taste account of the coffee. In addition, the optimization of the grinding process, combined with attentive maintenance, is necessary for maintaining performance in time. As we explore these essential elements, it becomes apparent that the effects extend beyond plain equipment option, affecting overall organization success in means that call for closer examination.

Understanding Grinder Types

When selecting a commercial coffee grinder, understanding the numerous kinds offered is vital for enhancing both flavor extraction and operational performance. The 2 key kinds of grinders are blade mills and burr grinders.

Inevitably, selecting the ideal kind of mill is essential to keeping quality and performance in coffee production, making it vital for businesses to spend in top notch burr mills for optimal outcomes.

Trick Features to Think About

Picking an industrial coffee mill requires careful factor to consider of numerous crucial features that can dramatically influence both efficiency and the total coffee experience. One of the primary aspects to review is the grinding device. Burr grinders are typically liked over blade mills, as they provide a constant work dimension, which is important for optimum extraction and flavor.

One more essential feature is the mill's capacity. Depending upon the quantity of coffee you require to process, select a model that can handle your demands without giving up rate or top quality. Additionally, think about the grind settings used. A functional mill with numerous setups permits you to tailor the work dimension to different brewing techniques, boosting the coffee's taste account.

The building material also plays a role in longevity and upkeep. Stainless-steel parts frequently provide longevity and are simpler to clean, which is vital for keeping health standards. Review the grinder's sound level, especially in a hectic café or production atmosphere, where excessive sound can be disruptive. Spending in a grinder that stabilizes these functions can considerably improve both functional performance and the quality of the coffee offered.

Optimizing Grinding Process

To achieve the ideal lead to coffee prep work, optimizing the grinding procedure is vital. The grind dimension considerably affects extraction, taste, and general top quality of the brewed coffee. Various brewing approaches require certain grind sizes; as an example, espresso requires a great work, while French press necessitates a rugged appearance. Understanding the partnership between grind dimension and brewing approach is the initial step in optimization.

Furthermore, checking the grinding rate can maximize the Read More Here procedure. Slower grinding often produces less heat, preserving delicate flavors and aromas. On the other hand, quicker grinding may produce extreme heat, negatively impacting the coffee's high quality.

Maintenance and Care Tips

Proper maintenance and treatment of commercial coffee mills are crucial for making certain optimal performance and durability. Regular cleaning is the structure of upkeep; deposit accumulation can impact flavor and grinding effectiveness. It is a good idea to clean up the mill after each use, cleaning down the outside and getting rid of any kind click over here of coffee grounds from the burrs.

In addition, check the grinding burrs for damage. Plain burrs can endanger work uniformity, so they must be replaced as necessary. Industrial Coffee Grinder. Occasionally calibrating the grinder is additionally critical, as this keeps the preferred work dimension for various developing approaches

Lubrication of moving components must be carried out according to the manufacturer's requirements, as this minimizes friction and prolongs the life of the tools. It is vital to utilize food-grade lubricants to ensure safety and security and compliance with health regulations.

Lastly, maintain the grinder in a dry and steady setting to stop rust and corrosion. By adhering to these upkeep and care ideas, operators can improve the performance of their industrial coffee mills while guaranteeing premium result and prolonged functional life.

Roi Analysis

Evaluating the return on investment (ROI) for commercial coffee mills is crucial for companies looking for to maximize their coffee manufacturing capabilities. A complete ROI evaluation aids identify the monetary feasibility of spending in high-grade grinders, allowing companies to evaluate the preliminary prices versus potential gains.

To conduct a detailed ROI evaluation, services need to consider several essential aspects. Initially, examine the acquisition rate of the mill, consisting of installation and any required modifications to existing infrastructure. Next off, determine operational costs, consisting of power usage, maintenance expenses, and labor performance renovations. High-performance grinders typically result in reduced grinding time and increased throughput, which can substantially improve productivity.

Furthermore, consider the impact on click this site item quality. Industrial Coffee Grinder. Superior mills produce an even more constant grind dimension, which can enhance flavor accounts and client fulfillment, eventually driving sales. By increasing the top quality of the end product, companies can warrant higher rates, resulting in increased earnings

Verdict

In recap, a commercial coffee mill plays an essential function in boosting both effectiveness and item quality within coffee production. Eventually, the calculated financial investment in a reputable mill contributes significantly to enhanced income and competitiveness in the coffee market.

In the affordable landscape of coffee manufacturing, selecting the best industrial coffee mill plays a pivotal duty in enhancing both efficiency and product high quality. The two key types of grinders are blade grinders and burr grinders. Within the burr mill group, there are level burr mills and conelike burr mills, each with its benefits. Burr grinders are usually preferred over blade mills, as they provide a constant grind dimension, which is important for ideal removal and taste.

In summary, an industrial coffee grinder plays a critical role in boosting both effectiveness and product top quality within coffee production.

Report this page